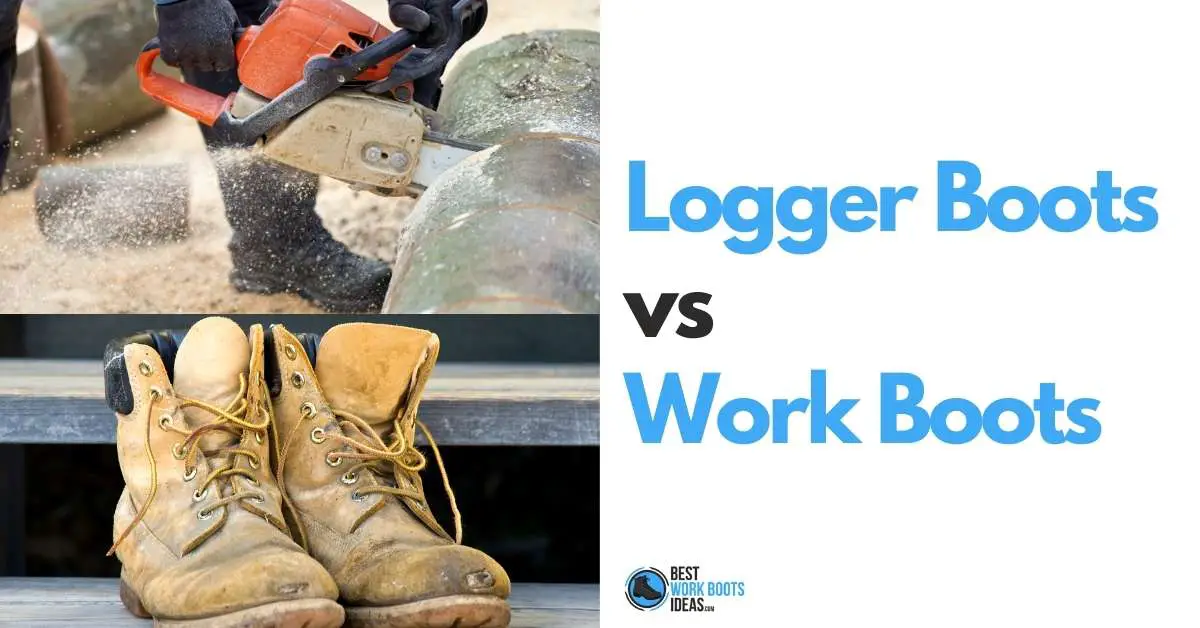

Logger Boots Vs Work Boots: Which ones are right for you?

There are many different styles of footwear, even within a category like work boots.

That’s why today I’m going to discuss the differences between logger and work boots.

There are many features that define logging boots.

In this article we’ll describe them and how they help lumberjacks and tradespeople.

Even if you’re not a lumberjack, you might still benefit from the unique features that logger boots offer.

Let’s get into the differences between loggers and your ‘typical’ work boots.

Contents

Characteristics of a Logger Boot

I want to quickly cover the generalities of logging boots.

Technically, loggers are a type of work boot, but they’re not interchangeable with your regular boot in all instances.

Below are some instances where they’re helpful, and others probably hurtful.

Why is that exactly?

Loggers are thick, hearty boots made to last.

At the very least they’re designed to help you climb hills in the wilderness.

At most they’re even designed to keep you safe from blades and chainsaws.

The overall height of logger boots usually doesn’t go lower than 9 inches and in many cases they’re much taller.

This is to prevent water or debris from getting into the boot while working.

It all protects the ankle and calf from any contact or cuts.

In general, it’s helpful to think of loggers as work boots XL in all senses.

They’re built out, they’re built up, and they’re built down.

If you work with timber or the forestry industry then you might be curious to know what the best logger boots are.

Performance Showdown: Loggers vs Work Boots

Weight In

Loggers are heavier than normal work boots in most cases.

Their added weight comes from a taller boot, thicker leather, and heartier outsole.

This makes loggers durable and protective, but a good amount of extra weight to carry around.

In my job as a residential contractor, it would have seemed ridiculous for me to walk into their house with loggers.

At times where I’ve been helping someone split or transport wood, the extra weight would and support would have been appreciated.

It’s all about perspective and circumstance!

I didn’t work in logging, but I have worked jobs where heavy duty protective boots would have been much more helpful than my ankle high work boots.

I’m thinking about my years in the mud working for a mason.

It’s no secret that thicker leather construction results in a bit of armor for our feet. So it’s not without benefit.

Work boots, by contrast, have shorter options (generally around 6/8 inches), less hearty heels, and other construction methods.

All of these factors make for a lighter boot on average.

This makes regular safety footwear substantially easier to move around throughout your work day.

If you’re dealing with semi-regular terrain, like most construction worksites, I would prefer the lighter, more mobile work boots.

Put the same pair of work boots on an logging site on a Oregon mountainside and they would seem comically inadequate.

It’s all about perspective and circumstance!

Measuring Up: Loggers and Work Boots

Loggers differ from work boots in regard to their average heights.

While most work boots are between 6 and 8 inches tall, the average logger starts at 9 inches and gets taller from there.

It’s not uncommon to have a pair of logger boots that are 11 or 12 inches tall.

The purpose of the extra tall throat to the calf is to protect the lower legs from any sort of flying debris or falling objects.

It may seem small, but it even makes a difference when it’s just a log falling off a stack at hip level.

It may not seem like much, but I promise you that when you’re dealing with the weights of timber, any added protection is welcomed.

Even just the little work I did for a landscaper as a younger man, I saw the value in the tall boots my employer used to wear.

We sometimes needed to large felled tree slices out of a pile and over to the wood splitter to prepare firewood.

As we would try to get one piece out, occasionally others would shift and roll onto your ankles.

This is where the added cushioning of leather and the boot’s padding makes a world of difference.

On the other hand, work boots are usually between 6 to 8 inches in height.

They focus more on mobility and flexibility than on protecting the shins and calves from any harm.

This is a reasonable choice when on a traditional union or construction site.

There’s usually not going to be anything that heavy you’re going to be handling or nearby, personally.

The same goes for private contracting.

There’s a level of control over what’s happening next.

With logging, and similar industries, you can’t predict when something’s going to snap, fall, slide, roll, or otherwise come at you unexpectedly.

Safety Features in Loggers and Work Boots

Both loggers and work boots have similar safety features, but to different extents.

The greater depth of safety features in logger boots is due to the job’s need for tools like chainsaws and other sharp tools.

A Logger’s job is considered one of the most dangerous jobs in the US.

It was reported that in 2019 there were just under 50 deaths.

There’s also the added risk of projectiles.

When trees are felled for logging, there’s the obvious risk of the tree falling or chunks of limbs crashing down; that much is obvious.

What is less obvious are the secondary risks after the tree has been toppled.

The branches and roots of a tree might not appear to be under a lot of pressure, but at times they can be.

Cutting into them can release something they were supporting which can release incredibly fast.

Imagine a seven foot maple tree branch being whipped at you in a second, not good.

Even in my own little life, I know of two stories in my home area of experienced tree experts being killed by projectiles and cutting the wrong root while trying to excavate the tree stump.

While in these two instances in Monmouth County, NJ that I remember would not have been changed

Metatarsal Guard

Loggers are more often equipped with a metatarsal guard than regular work boots, however either style boot can be found with this feature.

It’s the high likelihood that something heavy will eventually fall on your foot as a lumberjack that makes loggers more likely to have a Metatarsal guard.

However, it’s more common to have toe protection such as a steel toe for loggers.

Protective Uppers

Beyond the thickness of the leather which we’ve already discussed, loggers provide protection to the top of your foot with uppers that can be rated to protect your feet against almost anything you can imagine.

Materials like (xenon, kevlar), are embedded with chemical resistant coatings that prevent the chemicals from your gear from ever making its way inside your boot.

There are also uppers made from aramid fibers like Renzi or Kevlar that are rated to resist the cut of blades and even chainsaws.

Work boots are also found with these features, and this parallel between these two boot styles makes itself apparent again.

You can usually find the safety features of a work boot amplified and multiplied in a comparative logger.

Outsole

The outsoles of loggers are designed to be well suited to tough, highly irregular terrain.

Chunky, heavy, hearty outsoles that allow the boot to grip into muddy earth and hold on well.

Work boot outsoles vary depending on the marketed purpose of the boot.

The average boot outsoles are often designed with mixed applications in mind.

In addition to outdoor use, they are often slip and oil resistant designs for flat surfaces in commercial and industrial settings.

Heel

One of the most noticeable aspects of logger outsoles is the extra large heel.

I understand that with thicker outsoles comes a thicker heel, but even proportionately to the new size, the heel is larger.

The reason for this is so when workers are moving up an incline, their foot is closer to level as they step. It’s a way of tricking the body and also a good way to protect your back.

Some work boots advertise themselves as having a 90 degree raised heel, and do deliver better grip on tougher outdoor terrains.

That said, it’s more of an optional feature as opposed to an aspect of the boot’s design like with loggers.

In cases of factory and manufacturing work, there would be absolutely no advantage to an oversized heel.

It wouldn’t help anyone walk around a smooth cement floor and would actually make it more difficult.

Lug Pattern

The lugs seen on logging boots are among the most aggressive styles you can find in boots.

Made for the most rugged terrain, the lugs are deep, rigid, and will allow your feet to grab onto almost any earthy surfaces.

Work boots vary in terms of their lug patterns.

Some are more aggressive than others, and work boots generally try to fall in the middle of that scale.

It’s assumed the boots will be used both indoor and outdoor, so there are less aggressive patterns that grip well on flat surfaces too.

It’s all about knowing your work and the application of the lugs on your job.

A logger needs the most aggressive patterns, slightly more than oilfield workers, while asphalt workers want the absolute minimum tread pattern possible.

OSHA do provide some guidelines to Loggers and what footwear they should consider.

Construction Style

Logging boots are always made with heavy duty Goodyear or Storm Welt construction methods.

Work boots are sometimes made with these methods, but can also be constructed using cementing and other methods.

This is one of the primary factors that defines the differences between these two boot types.

Safety boots are sometimes built with construction styles that provide flexibility in exchange for boot longevity or durability.

The entire point of getting a logger is for exactly that, it’s durability and longevity.

Toe Cap

One of the similarities between these two styles of boots is that the majority of users will have some kind of toe protection.

This will either be in the form of a steel or composite toe.

As a logger, you’ll absolutely need your tootsies to be protected with a level of safety toe protection.

Wrap Up

Each job has a boot feature that is more important to it than any other, for loggers’ it’s durability and safety.

For bricklayers or contractors, it will be something different.

If you wanted to conduct a more realistic comparison of these styles of footwear then lineman boots vs logger boots is more appropriate.