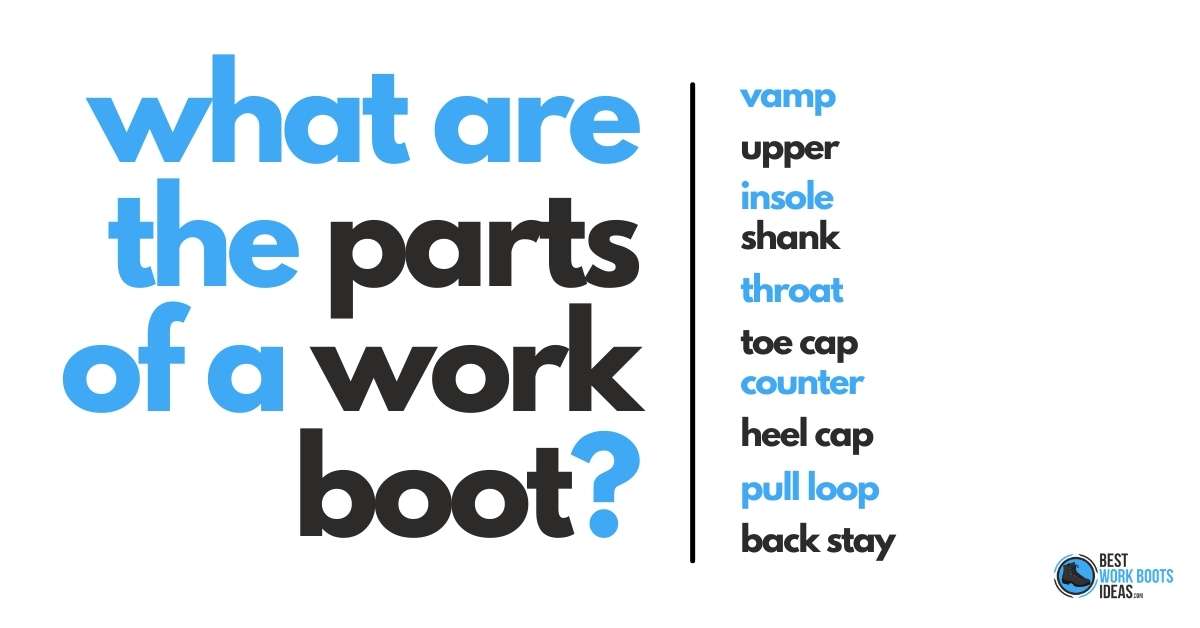

20 Parts of a Work Boot you Should Know Before Buying Your Next Pair

When looking to buy a new pair of work boots it’s helpful and necessary to know the proper terminology.

It’s strange to say, but most people make a purchase without knowing the names of the different parts of a work boot.

Having worked in construction and owning a contracting business, I’ve purchased and worn a number of work boots over the years.

Even with that background, I learned terms for different parts of the boot that I didn’t know existed or thought they were incorporated in other terms.

If you’re interested in diving a little deeper, check out the sources I used to create this article

- History of the Blucher style

- Insoles vs. Footbeds

- The structure of safety boots

- The anatomy of footwear

Beyond any title I’ve had or sources I’ve used, I appreciate a good pair of boots.

It’s to my surprise that there was so much that was new to me, and I’m a little ashamed that I wore work boots for so many years without knowing all the details of what I was counting on to protect my body.

No time to get critical about the past, let’s move towards the future! I want to get into detailing the different parts of a work boot.

Contents

The Upper

Upper refers to the areas that cover the top of the foot, front of the ankle, and back of the ankle/ heel. You will often see the entirety of the upper referred to as the exterior.

In short, it’s the part of the shoe that has no contact with the sole of your foot. The upper is the part of the boot responsible for waterproofing and some safety features.

You’ll often hear this referred to as a ‘leather upper’

Toe box / toe cap

Starting with the front of the foot is the toe box. As described by its title, the toe box is the curved area at the front of the boot that covers the area where your toes are.

Within the toe box is the toe cap. The toe cap’s purpose is to prevent your toes from being injured from any or from falling objects.

The toe cap has traditionally been made of steel but there are also alloy and composite constructions available.

Steel is cheap, heavy, and prone to conduct temperature and electricity. Alloys are lighter, and less prone to conduct temperature and electricity.

Composite materials are usually the lightest, and because of their non-metal construction, they conduct neither heat nor electricity and will not set off metal detectors.

You’ll often hear the toe cap being referred to as ‘steel toe’, ‘composite toe‘ and ‘aluminium toe’.

Vamp

The vamp is the part of the boot that extends from the toe box towards the ankle. It covers the top of the foot.

Essentially, the ‘front’ section of the boot.

Metatarsal Guard

In some boots you will see something featured called a metatarsal guard. This is a shield that protects the top of your foot in the areas of the vamp and/or throat of the boot.

You would use metatarsal guards in occupations where there is a risk of heavy objects falling on all of your feet. Welders are a good example of this.

Throat

The throat is the area of the boot from the base of the tongue to where you insert your foot.

Commonly known as the opening

Eyelets

The eyelets are the openings and/or hooks that receive your laces. They allow you to comfortably lace tie your boots.

You might also notice ‘speed hooks’ on some work boots which allow you to clip your laces on rather than feeding them rthrough.

Lace Stay

The lace stay is the part of the boot that eyelets are inserted into. This is usually an independent strip of leather or synthetic material that is stitched onto the quarters of the boot.

Tongue or Gusset

The tongue is the flap of material, usually padded, positioned underneath the laces and lace stays. It can be designed with pockets to prevent water from seeping in. It is responsible for a fair amount of the comfort a boot delivers.

Shaft / Quarter

The quarters are the pieces of material that run from the topline (the very top of the boot) down the side of your ankles and feet.

Blucher Style

Some boots have a piece of material that wraps from one side, around the front of the toe box, and ends at the same position of the other side of the boot.

It takes the place of the bottom quarters, and is known as a Blucher Boot. Not all boots have this design, but it’s good to be familiar with it if you come across it.

Back Stay

The back stay of a boot is the area behind your heel and achilles tendon.

Some boots have a back stay that extends the entire height of the boot. Other boots have an additional piece that wraps around the heel as well.

This additional piece, should you come across it, is called the foxing or the heel counter.

Pull Loop / Back Strap

The pull loop is something you will find on many, but not all boots. It’s exactly what it sounds like, a loop of material stitched into the back stay that assists you in pulling your boots on.

Soles

When speaking about a boot’s sole (yes, you will see a good number of puns if you’re checking out reviews) it’s important to remember that there’s more to a pair of boots’ soles than the portion that touches the ground.

Midsoles

The midsoles are the transitional area between the outsole and the footbed/insole, as their name would suggest.

Midsoles are made of steel, memory foam, polyurethane, ethylene vinyl acetate (EVA), or an aramid fiber, depending on their function.

Some midsoles’ strictly focus on providing cushioning and shock resistance, others offer puncture resistance, some a combination of both.

You should consider your top concern at work prior to reviewing your midsole options.

Outsoles

The outsoles are what people are referring to when they speak generally about a boot’s soles. That said, it’s important to know exactly what the outsoles are and what they do.

The outsoles are the portion of the boot that makes contact with the ground, and are among the materials that the uppers are connected to.

They can be connected using a form of Goodyear welt construction (stitching) or through modern construction methods that adhere the uppers to the outsoles using either heat or adhesives.

Outsoles are traditionally made of rubber but can also be made of polyurethane or other modern chemical compounds.

With their composition, along with the lugs (patterns and notches on the bottom of the outsole), they are responsible for giving the boot traction or any slip or chemical resistance.

You’ll find them either as a full or half sole.

Heel

The heel is a familiar part of boots as it shares its name with the part of the foot it supports. The Heel is responsible for support, stability, and traction.

The heel may also be used interchangeably with the terms such as ‘stacked heel’ and ‘heel cap’

Shank

The shank is one of the few parts of a boot that you can’t see with your eyes. Spanning the area between the heel and the front portion of the outsole, the shank is responsible for providing support for your arch and structural integrity for the boot.

Most often the shank is made of steel, but fiberglass and composite shanks are available for those seeking more flexibility in their boots.

Inners

Once again, this area of the boot is demonstrated by its name, but we’ll get into the specific components that make up the inners.

Insole and Foot bed

This is the component of boot (and shoe) construction that often creates confusion.

This insole is the part of the boot where you lay your foot. It can also be called the foot bed.

The insole is a part of the boot, so much so that it’s what the outsole is stitched to in the cases of welt construction methods.

It’s responsible for providing support, cushioning, shock absorption, and some even feature puncture resistance.

Insoles are made with a variety of materials ranging from memory foam to cork and everything in between.

It is NOT the same thing as insoles you would buy in a pharmacy.

While marketed as insoles, those pharmacy purchases for extra support are actually called foot beds or liners.

If you prefer to purchase your own specialized foot bed, just check to see that your boot’s foot bed is removable so you don’t damage your boots when you make the switch.

Lining

The lining is the material inside of your boot that makes contact with everything besides the bottom of your foot.

Most modern boots offer a lining with some form of moisture control and will be marketed as waterproof or breathable.

There are also moisture-wicking linings made of materials that draw moisture away from your feet as you’re wearing your boots.

Less common, but not unheard of, are linings that have antimicrobial qualities to prevent bacteria, fungus, and odor from developing in your boots’ inners.

Shoe Last

Whilst not a part of the work boot, a notable mention must go to the ‘shoe last’.

This is the mould on which the safety shoe is initially built on.

Know Your Boot

I hope this will be helpful for you as you purchase your next pair of safety boots. It’s always good to be an educated consumer, as you can get the product you need, not just what someone’s trying to sell you.

Get out there and give yourself the gift of the proper work boots!